Code 48 and a harsh shift

#1

So after Moab I have a couple problems. Code 48 which I have tried clearing twice and keeps coming back. Never had a CEL since doing the headgaskets I have had 2. Code 48 as per research is the stepper motor. This is controlled by the little sensor on the side of the throttle body correct?

I have found that I need to run test procedure 15 and 16 but cannot find the definition of those tests.. Thoughts?

Also who knows about shift patterns? My rover went from driving like a dream to having alot of trouble shifting. If I let off the gas to coast it upshifts (higher gears) twice then when I touch the gas again it slams into a much lower gear jolting the truck forward. Couple of observations, my kick down cable is in really bad shape. I bought a new one but it did fine with the cable before this started happening. This started after towing my pop up camper to and from moab. Not in moab. Not while 4 wheeling. I did have alot of trouble getting up vail pass and up to the eisenhower tunnel.

Any advice or related concerns after doing a head gasket will be very appretiated.

I have found that I need to run test procedure 15 and 16 but cannot find the definition of those tests.. Thoughts?

Also who knows about shift patterns? My rover went from driving like a dream to having alot of trouble shifting. If I let off the gas to coast it upshifts (higher gears) twice then when I touch the gas again it slams into a much lower gear jolting the truck forward. Couple of observations, my kick down cable is in really bad shape. I bought a new one but it did fine with the cable before this started happening. This started after towing my pop up camper to and from moab. Not in moab. Not while 4 wheeling. I did have alot of trouble getting up vail pass and up to the eisenhower tunnel.

Any advice or related concerns after doing a head gasket will be very appretiated.

#2

Sounds like its time for a trans fluid change.

I hope you were in 3rd gear while towing in the hills and mountains, to much shifting and the trans will get to hot and burn up the fluid.

Also while wheeling I usually stay in 2nd gear to prevent to many shifts, it also helps save the brakes by using the engine as a brake.

Hard wheeling in hot weather will do that too.

I have no idea about the code, AntiChrist and Cosmo will be your best bet.

I hope you were in 3rd gear while towing in the hills and mountains, to much shifting and the trans will get to hot and burn up the fluid.

Also while wheeling I usually stay in 2nd gear to prevent to many shifts, it also helps save the brakes by using the engine as a brake.

Hard wheeling in hot weather will do that too.

I have no idea about the code, AntiChrist and Cosmo will be your best bet.

#4

#5

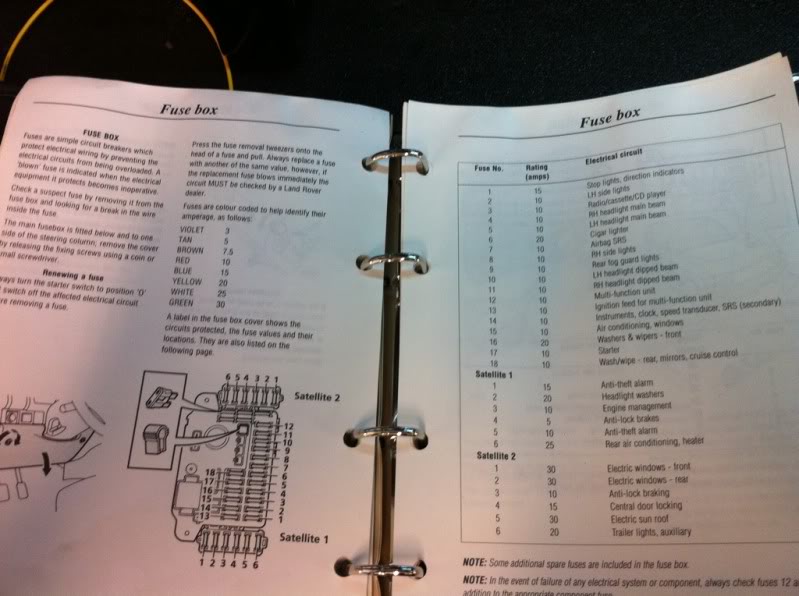

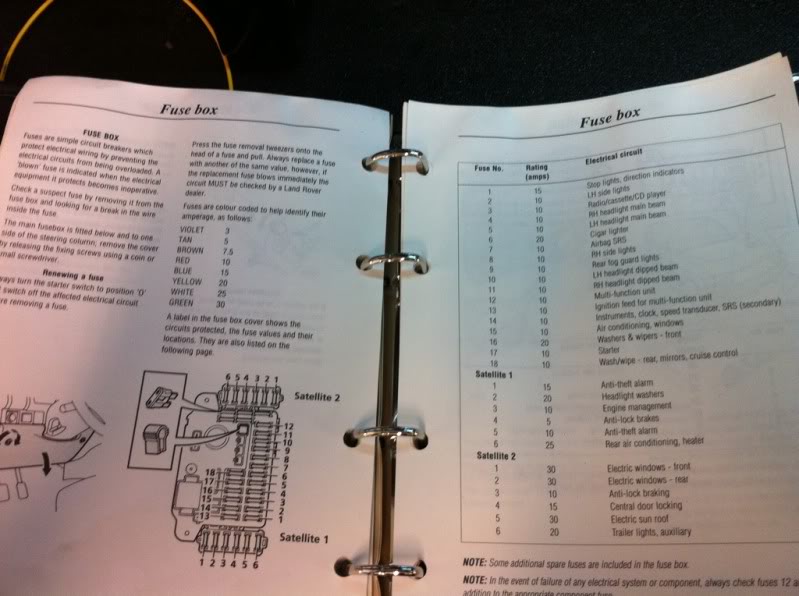

Why does this not match my actual truck?

I adjusted the idle screw as described in the rave and wanted to just pull the ecm fuse but it does not match what is in the manual.

Checked the trans fluid and it smells cooked. I also have a slightly bulging trans cooler line so I need to replace the cooler lines and kick down cable. Who has the best price on trans cooler lines?

I adjusted the idle screw as described in the rave and wanted to just pull the ecm fuse but it does not match what is in the manual.

Checked the trans fluid and it smells cooked. I also have a slightly bulging trans cooler line so I need to replace the cooler lines and kick down cable. Who has the best price on trans cooler lines?

#10

Sorry for the delayed response but I've been crazy busy lately. So let's get right to it........ 48 is in relation to the stepper motor OR something else causing your ilde to suck. <--- technical term.

The "little sensor" on the right side of the back of the plenum is the stepper motor... also called the IACV (idle air control valve). the other component on the front side of the throttle body, opposite side of the throttle linkage is the TPS. the TPS does not directly control the IACV. The VSS (speed sensor on the Txfer case) is responsible for telling the ECM which idle control mode to go into. If the vehicle is stopped then the IACV will actuate... when the vehicle is moving the IACV does not function. Again, with the vehicle moving and the throttle closed the TPS tells the ECM how to Fuel the injectors and the IACV is not moving... until the vehicle stops.

make sure you study the orientation of the plug on the IACV before unpluging it. It only goes on one way correctly but it can be forced on in an incorrect position... if that happens it will not work correctly. The IACV and its plug has a four pin setup. two cirtuits doing basically the same thing.

Pull the plug off and unscrew the IACV from the plenum. With your handy multimeter you should read between 40 to 60 ohms across two of the pins and the same reading across the other two pins. If you do have that reading then it is electrically good. Next the cone on the end of the motor needs to be clean as well as the cone seat in the plenum itself. You can get that with you favorite cleaning solvent and a q-tip. I also pull the cone itself out of the motor housing but some folks are uncomfortable with that... if done correctly no damage will result. (if you want to do this let me know) otherwise just spray a little WD-40 under the spring and onto the cone shaft.

once you have it all cleaned to test it you plug the connector back onto the IACV but don't screw it into the plenum. A partner is handy in this next step. Have someone put ignition switch into pos II but dont try to start it... the cone should wind itself "in" , retract toward the IACV housing as if it were opening if the IACV were screwed in place.

Place your hand over the hole in the plenum and start the engine. You should see cone movement. with your hand over the port you are acting as if the cone were all the way OUT. remove hand and see if cone tries to close... meaning it will extend just don't let it extend too much as it can fall out ( this is how you safely remove the cone frome IACV by-the-way). Your engine will idle all over the place and then will rev high with no hand over the IACV port.

if it is functioning go ahead and shut down engine and the cone should retract most of the way back into its normal resting position. reinstall ithe IACV and make sure to use a gasket where it mates to the plenum

A very dirty throttle body (butterfly valve) can cause the 48 too.. hell even a really bad misfire situation can cause this. 48 really just means the stepper motor is not able to function properly to maintain idle... either because it is faulty or because in order to get to the correct idle the stepper would be out of its range. Altering the base idle screw can cause this situation by the way. Has anyone messed with the base ldle screw in the top of the throttle body before you? that is NOT something you want to alter and I'd strongly suggest putting it back to the correct / previous setting.

You will find that the fuse to pull for the ecm is the Fuel Injection fuse found in the engine bay... in this case it may be best to disconnect the serial link plug on the ECM istlef as you probably have multiple codes. The fuse pull will cause all codes to disappear... but fear not they will return.

Also, pull the vac line for the Dizzy off at the plenum end and suck on it. if you have no suction / vacuum then your hose or diaphram to the vac advance on the dizzy needs to be replaced..... this will also let in unmetered air ( unmetered by the MAF) into the plenum and can cause an erratic idle.

Another "Also", test 15 and 16 are for the TPS. those "Test Proceedures" were from the RRC and EARLY Disco days. I'm pretty sure that all ended prior to '94 - '95. The RRC manual has the test proceedures listed in the Fuel Injection System section 19.

What steps did you follow when setting base idle? did you remove and plug all the PCV hoses and plug up the IACV port when adjusting the idle screw? There is a lot going on here.. maybe we can chat on the phone later on today? PM me if you'd like to.

The "little sensor" on the right side of the back of the plenum is the stepper motor... also called the IACV (idle air control valve). the other component on the front side of the throttle body, opposite side of the throttle linkage is the TPS. the TPS does not directly control the IACV. The VSS (speed sensor on the Txfer case) is responsible for telling the ECM which idle control mode to go into. If the vehicle is stopped then the IACV will actuate... when the vehicle is moving the IACV does not function. Again, with the vehicle moving and the throttle closed the TPS tells the ECM how to Fuel the injectors and the IACV is not moving... until the vehicle stops.

make sure you study the orientation of the plug on the IACV before unpluging it. It only goes on one way correctly but it can be forced on in an incorrect position... if that happens it will not work correctly. The IACV and its plug has a four pin setup. two cirtuits doing basically the same thing.

Pull the plug off and unscrew the IACV from the plenum. With your handy multimeter you should read between 40 to 60 ohms across two of the pins and the same reading across the other two pins. If you do have that reading then it is electrically good. Next the cone on the end of the motor needs to be clean as well as the cone seat in the plenum itself. You can get that with you favorite cleaning solvent and a q-tip. I also pull the cone itself out of the motor housing but some folks are uncomfortable with that... if done correctly no damage will result. (if you want to do this let me know) otherwise just spray a little WD-40 under the spring and onto the cone shaft.

once you have it all cleaned to test it you plug the connector back onto the IACV but don't screw it into the plenum. A partner is handy in this next step. Have someone put ignition switch into pos II but dont try to start it... the cone should wind itself "in" , retract toward the IACV housing as if it were opening if the IACV were screwed in place.

Place your hand over the hole in the plenum and start the engine. You should see cone movement. with your hand over the port you are acting as if the cone were all the way OUT. remove hand and see if cone tries to close... meaning it will extend just don't let it extend too much as it can fall out ( this is how you safely remove the cone frome IACV by-the-way). Your engine will idle all over the place and then will rev high with no hand over the IACV port.

if it is functioning go ahead and shut down engine and the cone should retract most of the way back into its normal resting position. reinstall ithe IACV and make sure to use a gasket where it mates to the plenum

A very dirty throttle body (butterfly valve) can cause the 48 too.. hell even a really bad misfire situation can cause this. 48 really just means the stepper motor is not able to function properly to maintain idle... either because it is faulty or because in order to get to the correct idle the stepper would be out of its range. Altering the base idle screw can cause this situation by the way. Has anyone messed with the base ldle screw in the top of the throttle body before you? that is NOT something you want to alter and I'd strongly suggest putting it back to the correct / previous setting.

You will find that the fuse to pull for the ecm is the Fuel Injection fuse found in the engine bay... in this case it may be best to disconnect the serial link plug on the ECM istlef as you probably have multiple codes. The fuse pull will cause all codes to disappear... but fear not they will return.

Also, pull the vac line for the Dizzy off at the plenum end and suck on it. if you have no suction / vacuum then your hose or diaphram to the vac advance on the dizzy needs to be replaced..... this will also let in unmetered air ( unmetered by the MAF) into the plenum and can cause an erratic idle.

Another "Also", test 15 and 16 are for the TPS. those "Test Proceedures" were from the RRC and EARLY Disco days. I'm pretty sure that all ended prior to '94 - '95. The RRC manual has the test proceedures listed in the Fuel Injection System section 19.

What steps did you follow when setting base idle? did you remove and plug all the PCV hoses and plug up the IACV port when adjusting the idle screw? There is a lot going on here.. maybe we can chat on the phone later on today? PM me if you'd like to.

Last edited by Cosmic88; 04-12-2011 at 11:06 AM. Reason: details and spelling