Oil lamp and ticking at 170k: Suggestions on where to start

#241

#242

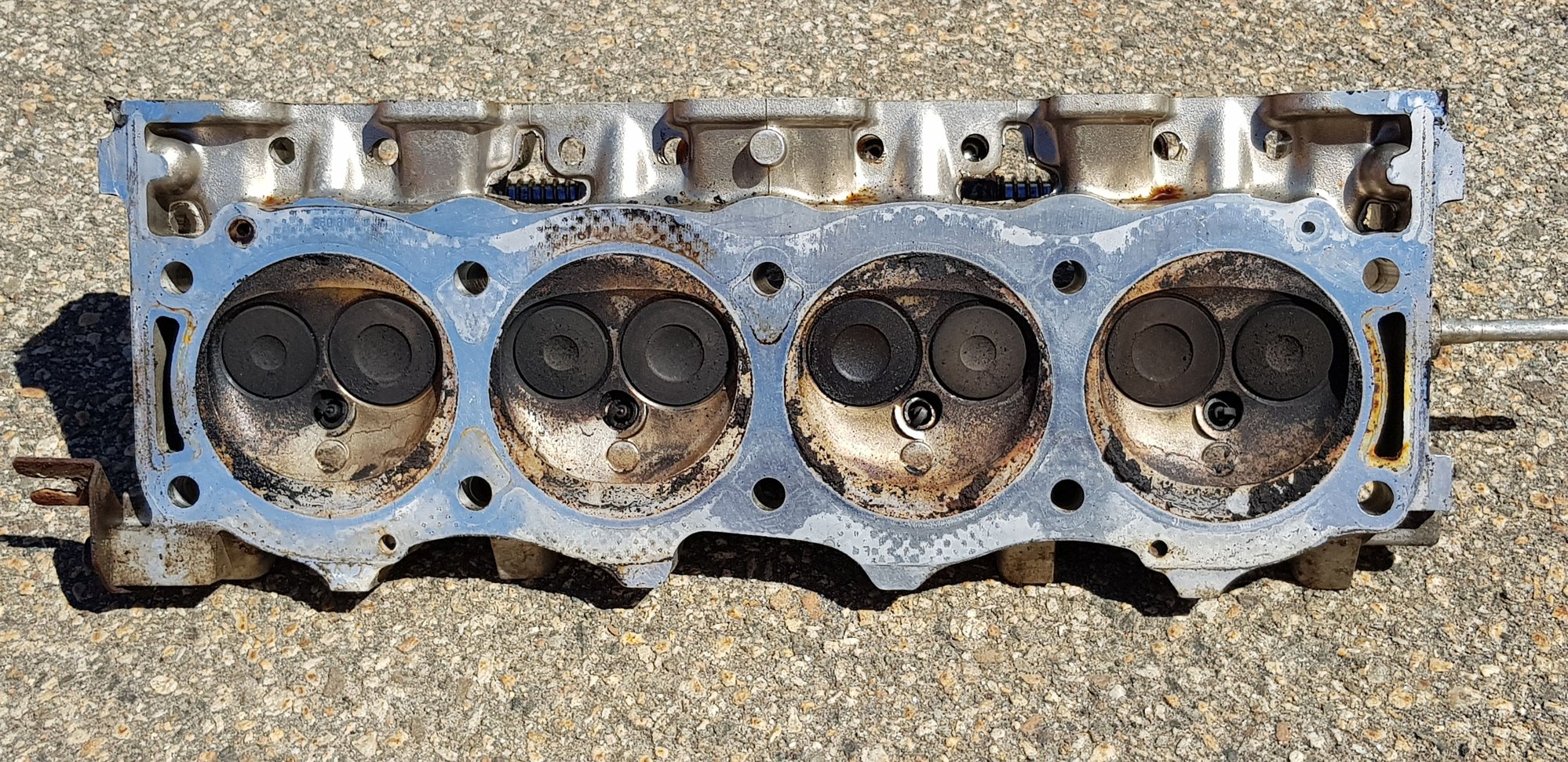

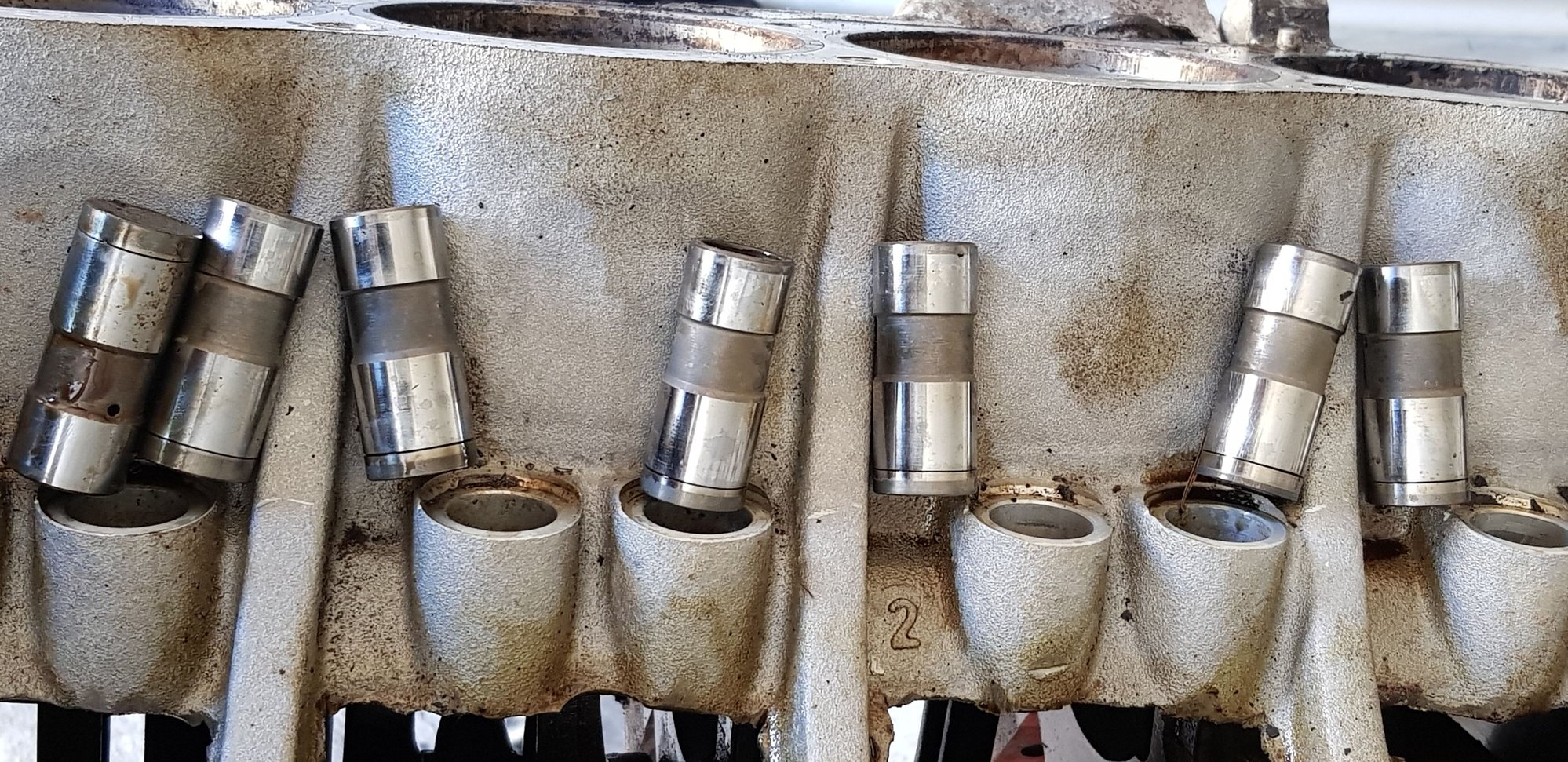

Nothing looks bad so far. Did you check the oil pressure like I suggested before pulling it out? The oil light on indicated you did not have oil pressure, but it woudl help to know what the reading actually was. Was it on all the time, or only at idle? What do the oil pump gears look like? All the carbon seems to indicate it was getting flooded with fuel or oil. We need better pics of the camshaft to verify the bearings are still in place (common issue on factory blocks, but would not expect a Turner engine to have problems). Also, need close up pics of the cylinder walls. I want to see the finish. You shoudl be able to still see the crosshatch honing marks in them.

When my truck was at the shop shortly after the ordeal I had them do a oil pressure test and they said there was no pressure at all in the block.

#243

#244

#245

#246

#247

The oil pump appeared to be in good shape with no damage. The truck ran okay for about a 11 months from the date the Turner block was installed. The only issues I was having throughout that year was persistent misfires on multiple cylinders. I replaced the coils, plugs, wires and fuel injectors and I thought all was well until December when the engine lost oil pressure abruptly while the truck was warming up in my driveway. The truck was never driven while the oil light was on.

#248

I've been in touch with Turner Engineering and have been providing them with pictures and updates on my progress with the engine teardown. This is their feedback.

"Dear Julian

Thank you for the photographs.

The bearings look like they have been partially starved of oil for a short

time, maybe even on original start up. The bearings do not look very nice

but the damage is not sufficient to cause knocking. The front bearing has

sat with water between the crankshaft and the bearing. This will have

happened sometime post-delivery. A crankshaft in that kind of condition

would have been reground. The water can go into the front bearing by

capillary attraction (water spilt down the front of the engine).

What is more of concern is the considerable amount of carbon in the

cylinders particularly no 1 front cylinder that has material that looks like

carbon and/or detonation damage that has been impacting on the cylinder

head. This maybe your problem. It cannot be seen clearly but there maybe

some detonation damage to no 1 piston

I see no quality related issues that would have been a contributory factor

to the knocking problem you described. When supplied the engine was devoid

of any carbon deposits, detonation damage or water marking of the crankshaft

and/or run related oil starvation. The most probable cause of your knocking

is combustion abnormalities and/or detonation"

"Dear Julian

Thank you for the photographs.

The bearings look like they have been partially starved of oil for a short

time, maybe even on original start up. The bearings do not look very nice

but the damage is not sufficient to cause knocking. The front bearing has

sat with water between the crankshaft and the bearing. This will have

happened sometime post-delivery. A crankshaft in that kind of condition

would have been reground. The water can go into the front bearing by

capillary attraction (water spilt down the front of the engine).

What is more of concern is the considerable amount of carbon in the

cylinders particularly no 1 front cylinder that has material that looks like

carbon and/or detonation damage that has been impacting on the cylinder

head. This maybe your problem. It cannot be seen clearly but there maybe

some detonation damage to no 1 piston

I see no quality related issues that would have been a contributory factor

to the knocking problem you described. When supplied the engine was devoid

of any carbon deposits, detonation damage or water marking of the crankshaft

and/or run related oil starvation. The most probable cause of your knocking

is combustion abnormalities and/or detonation"

Last edited by TRIARII; 06-10-2019 at 02:38 PM.

#249

I see nothing so far to cause this. Where the rocker tower bolts tight? Pickup tube in place and not blocked? Even spun bearings and walked cam bearings have some oil pressure, albeit low. The carbon build up is concerning, but not unexpected given the running conditions. Did the replacement engine have the same misfire problems?

#250

I see nothing so far to cause this. Where the rocker tower bolts tight? Pickup tube in place and not blocked? Even spun bearings and walked cam bearings have some oil pressure, albeit low. The carbon build up is concerning, but not unexpected given the running conditions. Did the replacement engine have the same misfire problems?

The original engine (pre Turner block) did not misfire. Instead it had a typical ticking noise. The crankshaft bearings were in rough shape. The multiple cylinder misfires only came around after the Turner block was installed; maybe 3 months after the new block was installed was when the engine started misfiring. The mechanic who installed the new block advised I check the plugs and wires and injectors. I ended up replacing the wires and plugs 3 separate times then went on to replace the coils and injectors. But every now and again the misfires would come back. The last time I started the truck everything sounded fine: started the truck on a cold single digit day on Christmas, let it warm up for maybe 30 minutes give or take. When I came back out to my truck the oil pressure light was illuminated, the check engine light was flashing, the engine was idling real rough and the sounds I recorded in the videos above were apparent. Sounded like the truck was also misfiring. I immediately turned off the truck then check the engine oil but it was full. I double checked the spark plugs and wires to make sure everything was properly installed and tight and everything checked okay. Several hours later I turned the truck on again. Immediately all the same symptoms from early were apparent. Shut it off and had it towed to a shop. They turned the truck on again just long enough so they could hear it for themselves then they pressure tested the block and told me there was no oil pressure at all. I had them drain the oil, pull the sump and inspect the pickup tube to see if it was cracked or clogged. Negative. Then I had them pull the front cover to inspect the oil pump gears. All seemed in order and no visible damage. Only thing they found was some scoring on one of the crankshaft bearings along with some metallic residue. After that I had the truck towed to a storage lot where it sat for a year or more until I was able to pull the engine myself.

The mechanic who installed the block is a friend who I trust. The supplier who provided me with the block is a top notch reputable manufacturer of Land Rover engines. They have excellent reviews and solid track record with customers. I was very selective about the whole thing. Unfortunately I was out of the state working a seasonal job while the engine was being swapped into my truck. I did not witness the work being performed. I cant determine who or what caused the engine failure. It's a sticky situation but iam trying to make the most of it. Iam slowly learning the workings of the engine and eventually I will rebuild it. The only issue I forsee is the fact that I don't have a donor vehicle to test the rebuilt engine was its complete. Iam not going to install it in my white D2 because my truck already had a major engine overhaul in 2009. But Iam going to do the head gaskets pretty soon and will use the spare heads to swap over once they have been machined and inspected at a shop. Then I'll use my current heads for the Turner block down the road.

Iam not sure what iam looking for but I imagine the crankshaft needs to be pulled and machined or replaced. The scoring on it leaves me feeling uneasy. Iam also concerned about the pushrods. I understand that you are suppose to label the rods before you take them out because they need to be inserted exactly where they were pulled from. However I got carried away when removing the heads and forgot to label them. Iam thinking about installing new lifters and switching to adjustable pushrods. The block currently uses a sports camshaft and part of me wonders if that could have caused some imbalances with the engine so maybe buy a new stock camshaft. I'am also going to replace the crankshaft bearings and inspect the pistons.