slipped sleeve? (pics)

#1

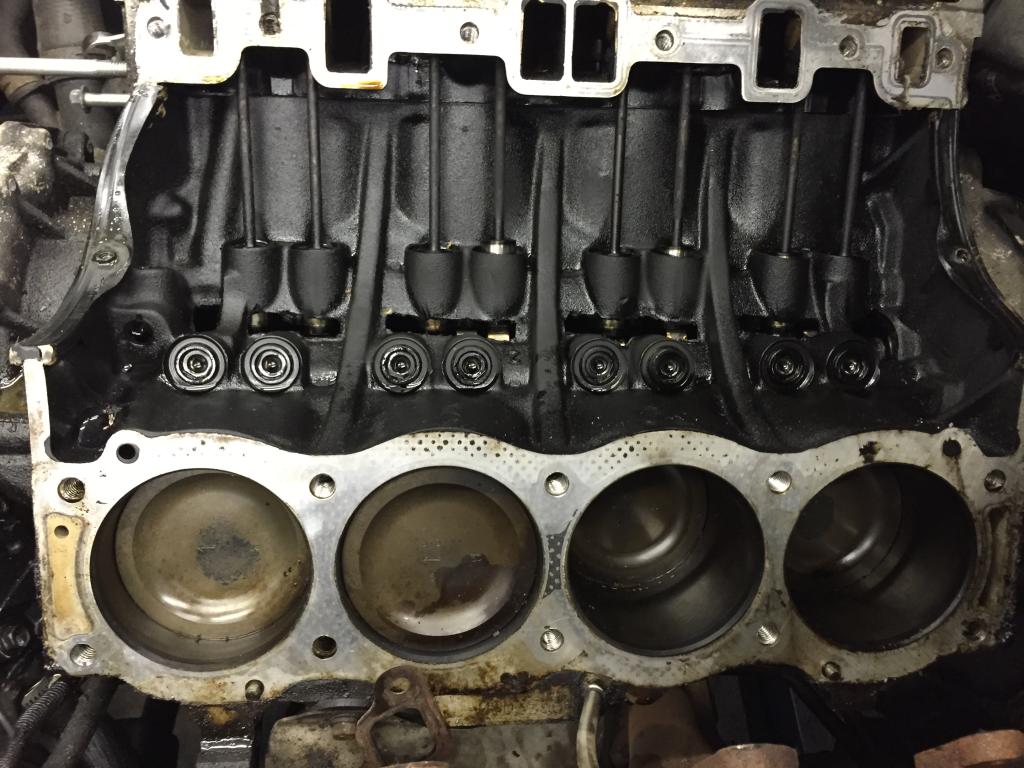

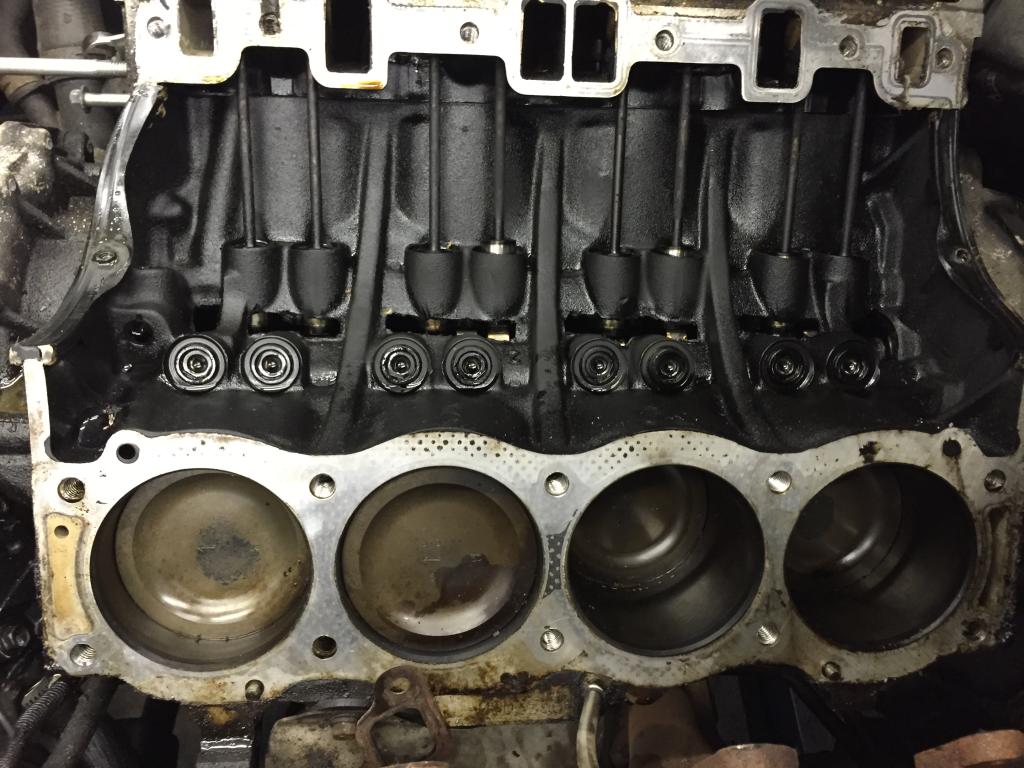

Started pulling apart the motor in my 04S with 120k. Previous owner says that it overheated and shut off.  I never heard it run so I dont know if it ticked or not.

I never heard it run so I dont know if it ticked or not.

I can also feel a ridge on the deck but no steam cleaned pistons...

What is my next step here? Pull the motor and pressure test it? I know you can pressure test it in the car but Im worried about the condition of the rotating assembly after seeing all the sludge and burnt oil up top

I never heard it run so I dont know if it ticked or not.

I never heard it run so I dont know if it ticked or not.I can also feel a ridge on the deck but no steam cleaned pistons...

What is my next step here? Pull the motor and pressure test it? I know you can pressure test it in the car but Im worried about the condition of the rotating assembly after seeing all the sludge and burnt oil up top

#2

If the sleeve is above the deck it will have to be surfaced or the sleeve will have to go down. If you take the engine out, have them pressure test it first to see that the block isn't cracked and have them check that the cylinders are still round and that the block is square and not warped, since he ran it hot. Do all of that before you spend any money on the engine.

If all that checks out have it decked and pin the sleeves since you will have it out anyway. I don't know if you could get the sleeve back down with it in the truck.

Also if the sleeve is above the deck you will need to have a good check on the head since the sleeve was hammering on it.

If all that checks out have it decked and pin the sleeves since you will have it out anyway. I don't know if you could get the sleeve back down with it in the truck.

Also if the sleeve is above the deck you will need to have a good check on the head since the sleeve was hammering on it.

Last edited by RicketyTick; 10-03-2014 at 11:48 AM.

#3

#4

I've seen videos of the liners being pulled out of the block after it was heated with a torch so I imagine the opposite could be done but not in the truck. I would say at the very least get the block up to 220 or 230 and see if the liner can be pressed back in enough to make it flush. They are tapered so if you just deck the block then you will have a liner that isn't as snug as it could be. Then you could pin them That's assuming the block passes a pressure test.

#5

I've seen videos of the liners being pulled out of the block after it was heated with a torch so I imagine the opposite could be done but not in the truck. I would say at the very least get the block up to 220 or 230 and see if the liner can be pressed back in enough to make it flush. They are tapered so if you just deck the block then you will have a liner that isn't as snug as it could be. Then you could pin them That's assuming the block passes a pressure test.

I read what I think everybody else read on robinsonservice website but, I think they were referring to the bevel at the top inside of the liner which they called a taper and not that the outside of the liner is tapered.

This is what they said which is kind of confusing.

" As you can see, the steel liners are tapered at the top, sort of like you’d bore a countersink hole if the engine block were a piece of wood. . . ."

And in the sentence above they say "as you can see" referring to the image below and in the image below you can't see anything but the inside of the liner and the small inside bevel.

That is why I think they were referring to the inside taper/bevel.

I believe that is why everyone started saying the sleeves were tapered. I could be wrong wouldn't be the first time. If anybody has anything definite please step forward.

Then they also went on to say:

"In this image (below) you can see the step that prevents the liner from sliding down into the crankcase on these newer motors (referring to post 2000 engines). In this design, the liner can’t actually move more than a few thousandths of an inch unless they failed to seat it against the step at the factory."

And as we know that is why they slip (move up and down) because some weren't seated properly at the factory before they were machined at the top leaving room for them to move up and down. It usually starts after an engine is ran hot.

My thinking is if they were actually tapered they wouldn't depend on a step to keep them from falling down, a taper (either at the top or the entire length of the liner) would prevent it and not allow them to fall. But since some weren't pressed in all the way to the step before machining they move up and down a little or a lot.

I myself don't think they are tapered, I think that was something someone misinterpreted and snowballed in the forums.

But I have no way to prove or disprove this theory until I have a loose liner in my hand to measure (and an old liner may not be round enough after being removed to measure on the outside accurately if it's a very slight taper) or until I can mic the inside of an empty liner bore in a block above the bottom step and at the top.

Anyway, may have nothing to do with the op's situation, but since I have read so many people saying they were tapered as a fact, I would just like to know for sure.

Last edited by RicketyTick; 10-03-2014 at 09:58 PM.

#6

#7

#8

Probably because they sell top hated blocks.

#9

If the sleeve is above the deck it will have to be surfaced or the sleeve will have to go down. If you take the engine out, have them pressure test it first to see that the block isn't cracked and have them check that the cylinders are still round and that the block is square and not warped, since he ran it hot. Do all of that before you spend any money on the engine.

If all that checks out have it decked and pin the sleeves since you will have it out anyway. I don't know if you could get the sleeve back down with it in the truck.

Also if the sleeve is above the deck you will need to have a good check on the head since the sleeve was hammering on it.

If all that checks out have it decked and pin the sleeves since you will have it out anyway. I don't know if you could get the sleeve back down with it in the truck.

Also if the sleeve is above the deck you will need to have a good check on the head since the sleeve was hammering on it.

So then "pinning" the sleeves will do NOTHING to keep them from moving up...and the step (we're not questioning the existence of the step, right?) would keep the sleeve from moving down...

Why then, would you need to pin the sleeves on a 4.6L block?

Last edited by sdhow; 10-03-2014 at 03:16 PM.

#10

At any rate, pinning would keep them from moving up or down. It pins in through the side but, the liner would still need to be flush at the top. It could not sit above the deck surface. The ones that slip weren't seated all the way and they slip down to the step and back up to the head. If they were seated properly from the factory they couldn't move down, but once the factory milled the surface and tops of the liners with it sitting 1/8" or so above the bottom seat it can't now be pushed back all the way down to the step, that would leave a gap at the top. It has to stay flush at the top and that leaves the gap at the bottom, and pinning just keeps it from moving either way up or down.

There are threads on the forum by people who have pinned. It's not the perfect fix, like drowssap says, but still it's a cheap alternative to spending $6K or $8K on a top-hated engine. If I personally had to spend $6K or $8K on my truck to keep it going this late in the game, I would probably have to scrap it. Pinning is a last ditch effort to save an engine that has a slipped sleeve but doesn't have a cracked block and in a truck that is not worth spending $6K-$8K on. If the engine was still together I would first try a 180 thermostat before pinning.

If it won't hold pressure or is leaking coolant into a bore, no amount of pinning will do any good. The only fix for that would be a new block or a guaranteed good used block.

Last edited by RicketyTick; 10-03-2014 at 10:09 PM.