Engine noise and inspection camera!

#1

Hello All!

So long story short, I'm a newer member, bought my 2003 Discovery knowing it has an engine noise but now I need to figure out what it is so I can go about fixing it. It's making a tapping noise only when it gets to operating temp, dead silent when started cold and for about the first 5-10 minutes of running. As of right now I have the top decently torn down and have an inspection camera coming in the mail. I thought it might have simply been a broken rocker arm or something obvious once I pulled the valve covers, but still don't see anything obvious wrong. Maybe I've got a liner or 2 wandering around? If I stick the inspection camera in the cylinder would I be able to visually tell if one has slipped around or not? Just trying to get myself a game plan so that I can make 100% sure I get the problem fixed the first time around. It's a pretty dang loud tapping and everyone stares as it drives past hahahaha. Thanks in advance for any light anyone might be able to shed on the situation!

So long story short, I'm a newer member, bought my 2003 Discovery knowing it has an engine noise but now I need to figure out what it is so I can go about fixing it. It's making a tapping noise only when it gets to operating temp, dead silent when started cold and for about the first 5-10 minutes of running. As of right now I have the top decently torn down and have an inspection camera coming in the mail. I thought it might have simply been a broken rocker arm or something obvious once I pulled the valve covers, but still don't see anything obvious wrong. Maybe I've got a liner or 2 wandering around? If I stick the inspection camera in the cylinder would I be able to visually tell if one has slipped around or not? Just trying to get myself a game plan so that I can make 100% sure I get the problem fixed the first time around. It's a pretty dang loud tapping and everyone stares as it drives past hahahaha. Thanks in advance for any light anyone might be able to shed on the situation!

#3

You need to remove the heads and run your finger nail across the liner/block seam. If you feel a ridge at the seam it's dropped or proud of the bore. Straight edge (machinist rule) works too, looking for daylight under the rule. A dial indicator on a beam works too. Measure the block deck, measure the liner height. Usually when they travel with the piston you'll see a pronounced seam (darker, larger) whereas between one that doesn't move the seam will almost disappear against the block. Coolant will cause discoloration at the seam, it's another sign it's moved.

What I would do since you know it has a high probability for liner movement already why not just have the block top hatted and be done with it? I'd toss some other goodies at it as well and then button it up and call it better than new.

What I would do since you know it has a high probability for liner movement already why not just have the block top hatted and be done with it? I'd toss some other goodies at it as well and then button it up and call it better than new.

#4

You need to remove the heads and run your finger nail across the liner/block seam. If you feel a ridge at the seam it's dropped or proud of the bore. Straight edge (machinist rule) works too, looking for daylight under the rule. A dial indicator on a beam works too. Measure the block deck, measure the liner height. Usually when they travel with the piston you'll see a pronounced seam (darker, larger) whereas between one that doesn't move the seam will almost disappear against the block. Coolant will cause discoloration at the seam, it's another sign it's moved.

What I would do since you know it has a high probability for liner movement already why not just have the block top hatted and be done with it? I'd toss some other goodies at it as well and then button it up and call it better than new.

What I would do since you know it has a high probability for liner movement already why not just have the block top hatted and be done with it? I'd toss some other goodies at it as well and then button it up and call it better than new.

#5

Sometimes it is and sometimes it isn't obvious. The other issue with the 03/04 blocks is cracks behind the liners which again might be or might not be obvious. Being over ten years old there's a chance it's poor oil changes that have rockers a knocking and I guess you'll know when you know. I went through my engine the first time I cracked it open and found all kinds of neglect including occluded oil galleys all throughout the top end to include the rockers themselves. I was fortunate enough to get to it when I did otherwise there would have been a sure failure.

#6

Sometimes it is and sometimes it isn't obvious. The other issue with the 03/04 blocks is cracks behind the liners which again might be or might not be obvious. Being over ten years old there's a chance it's poor oil changes that have rockers a knocking and I guess you'll know when you know. I went through my engine the first time I cracked it open and found all kinds of neglect including occluded oil galleys all throughout the top end to include the rockers themselves. I was fortunate enough to get to it when I did otherwise there would have been a sure failure.

Also another weird thing that I forgot to mention before is that even with the loud tapping/knocking, the knock sensors aren't picking up anything at all. It even passed smog knocking away like crazy. Just found that peculiar and maybe a really good clue however I'm not really sure what that would mean for sure.....

#7

#8

you will not see a slipped liner with an inspection camera, but what you probably will see is a nice shinny piston.

If you have one of two pistons that are not black like the others, then they are being steam cleaned somehow.

as long as you have the camera you have nothing to lose

If you have one of two pistons that are not black like the others, then they are being steam cleaned somehow.

as long as you have the camera you have nothing to lose

#9

Also another weird thing that I forgot to mention before is that even with the loud tapping/knocking, the knock sensors aren't picking up anything at all. It even passed smog knocking away like crazy. Just found that peculiar and maybe a really good clue however I'm not really sure what that would mean for sure.....

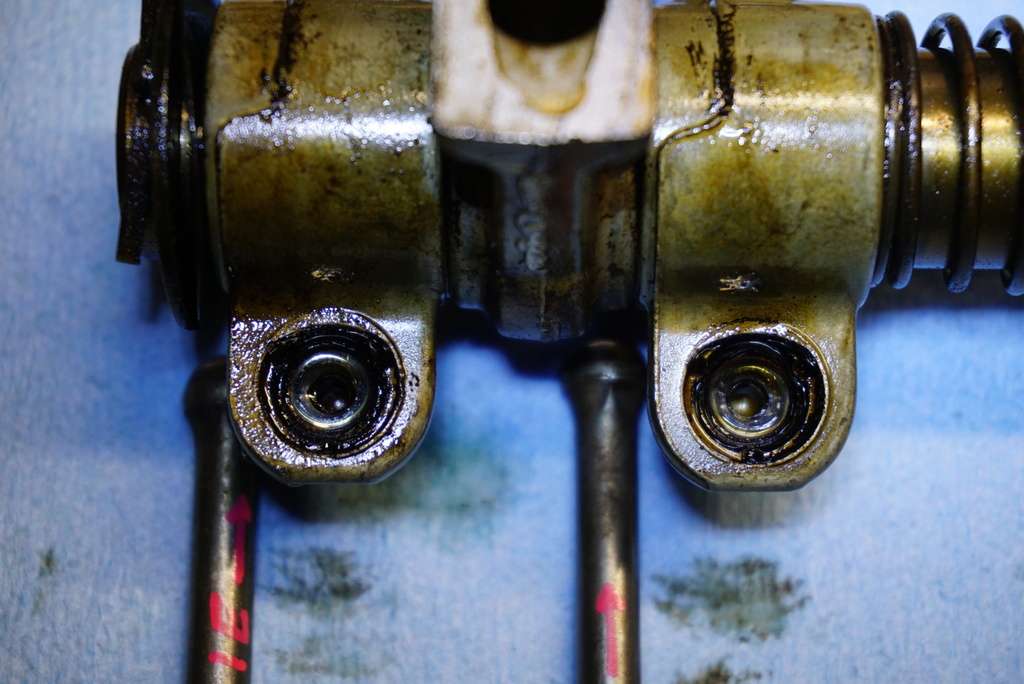

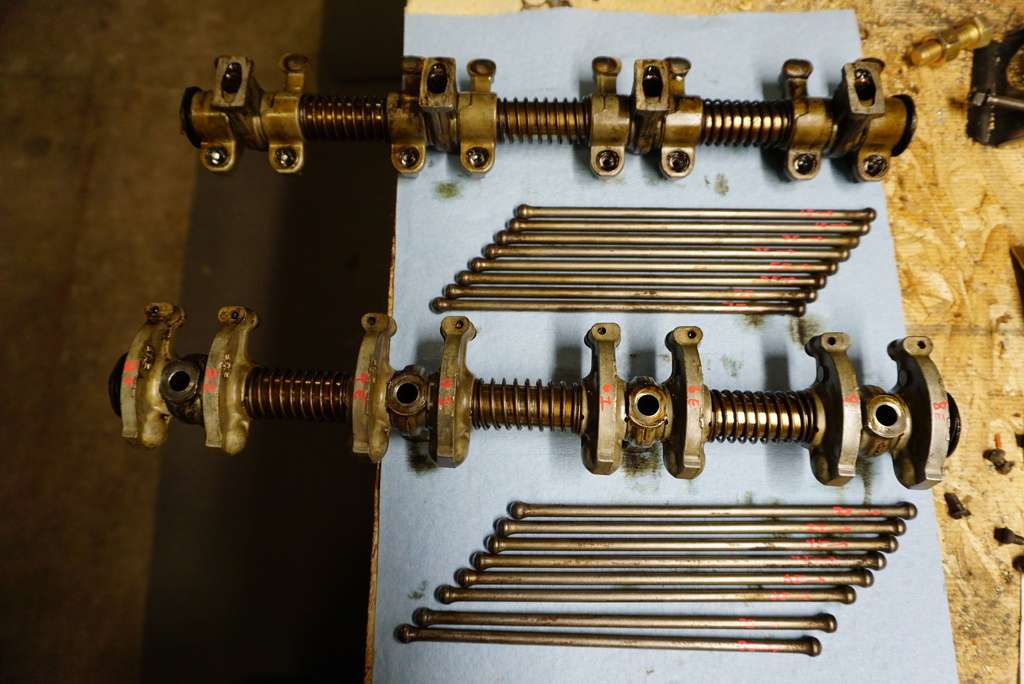

When you look at the push rods they're supposed to be round like a ball, not mushroom shaped. Rockers oil from the shaft to the rocker to the push rod cups. That's where I found mine occluded, hard carbon. A soak in Chemtool did most of the work on em. A dental pick did the rest. Also looking for missing buttons on the rockers, they contact valve stem, spin it. Not uncommon to find one missing.......... clack, clack, clack.

#10

If you can, perform a compression test on the engine fully warmed up. I'm not saying it's the be all, end all but it might give you readings on cylinders to look at if you do pop the top. The compression test is one of my favs because of the high pressure.

When you look at the push rods they're supposed to be round like a ball, not mushroom shaped. Rockers oil from the shaft to the rocker to the push rod cups. That's where I found mine occluded, hard carbon. A soak in Chemtool did most of the work on em. A dental pick did the rest. Also looking for missing buttons on the rockers, they contact valve stem, spin it. Not uncommon to find one missing.......... clack, clack, clack.

When you look at the push rods they're supposed to be round like a ball, not mushroom shaped. Rockers oil from the shaft to the rocker to the push rod cups. That's where I found mine occluded, hard carbon. A soak in Chemtool did most of the work on em. A dental pick did the rest. Also looking for missing buttons on the rockers, they contact valve stem, spin it. Not uncommon to find one missing.......... clack, clack, clack.

Before I forget, those rocker mounting bolts, are those a torque to yield bolt? I didn't think they were but I can't remember off the top of my head so better safe than sorry, haha.