D2 driveshafts

#1

#4

That's around the mileage when the stock ones start failing.

If you rebuild it with greaseable u-joints and grease it properly and every 5,000 miles, then you won't need to rebuild it again for many many miles (I have about 150k on mine).

If you aren't going to grease it every 5k miles, then rebuild it with sealed u-joints, and plan on doing it again every 50-60k.

If you rebuild it with greaseable u-joints and grease it properly and every 5,000 miles, then you won't need to rebuild it again for many many miles (I have about 150k on mine).

If you aren't going to grease it every 5k miles, then rebuild it with sealed u-joints, and plan on doing it again every 50-60k.

#5

It is not recommended to be done at the 60K, it has to be done as soon as you realize it hasn't been done.

Mine failed at 37,000 miles, I was lucky cause I knew what to look for. The problem is, when it fails, and they do, if you are at highway speed, it can destroy your tranny also so get it rebuilt/replaced ASAP and not by the dealer who will install another one that will have the same problem.

Mine failed at 37,000 miles, I was lucky cause I knew what to look for. The problem is, when it fails, and they do, if you are at highway speed, it can destroy your tranny also so get it rebuilt/replaced ASAP and not by the dealer who will install another one that will have the same problem.

#8

Yes I also ordered the centering ball kit. I have never done this but am very mechanicaly inclined and my friend is a master mechanic by trade. It would be good however to have some foreknowledge - what problems should I expect. Is this work explained somewhere on this forum? Any advice would be appreciated. Thanks.

#9

Here are some instructions that were put together based on information I and others posted on Discoweb.

http://www.box.net/shared/jbgsi67tnx...9364:131879309

Just a couple of additions. I personally prefer using a center punch to mark the propshaft component orientation. You don't have to worry about them getting rubbed off, plus it lets you clean it and paint it, if you want, while it's apart.

Here's another set:

http://www.discovery2.co.uk/propshafts.html

Be sure to lube the u-joints well before putting it back in service. The grease from the factory is just to prevent the u-joints from rusting and to hold the needle bearings in place. The correct way, which is the method I use, is to lube them well before you install them. Of course you have to retain the end caps. I just clamp it in a vice and use a few wraps of electrical tape to retain the others.

Once you have it installed, lube it at minimum every 5k miles. I do it every oil change as it makes it easier to remember. And you must see new grease coming from around all 4 seals on each u-joint. Don't let anyone tell you "a couple of pumps". Sometimes it can take up to 6 or 8 pumps when it's been in service for a while. You need to do that to flush any contaminants out. This is important. If you're not going to do it, you're better off using sealed u-joints.

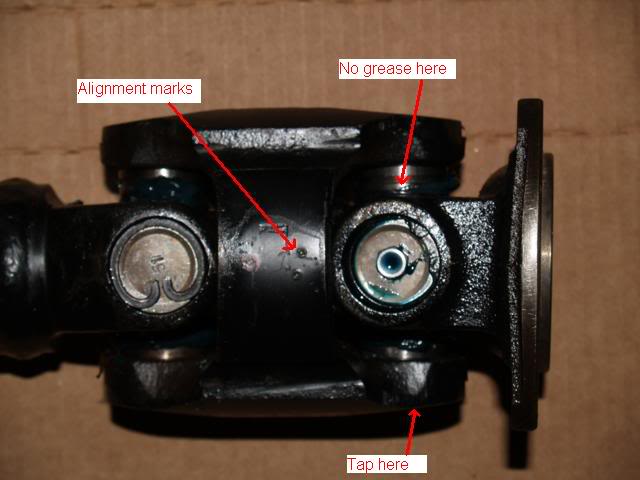

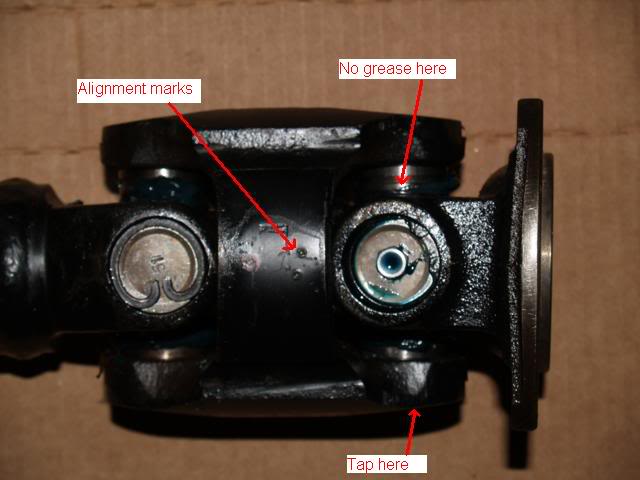

If you have u-joints that have the zerk fitting in the end cap (which is what I prefer as it makes lubing the DC end easier) you can replace them with the flush style, as seen on this shaft I rebuilt.

When you're lubing it, if you can't get any grease coming out where shown, then tap the opposite side of the yoke as indicated.

On the slip joint, if you use one, you won't have to remove it and replace the plug every time you want to grease it.

http://www.box.net/shared/jbgsi67tnx...9364:131879309

Just a couple of additions. I personally prefer using a center punch to mark the propshaft component orientation. You don't have to worry about them getting rubbed off, plus it lets you clean it and paint it, if you want, while it's apart.

Here's another set:

http://www.discovery2.co.uk/propshafts.html

Be sure to lube the u-joints well before putting it back in service. The grease from the factory is just to prevent the u-joints from rusting and to hold the needle bearings in place. The correct way, which is the method I use, is to lube them well before you install them. Of course you have to retain the end caps. I just clamp it in a vice and use a few wraps of electrical tape to retain the others.

Once you have it installed, lube it at minimum every 5k miles. I do it every oil change as it makes it easier to remember. And you must see new grease coming from around all 4 seals on each u-joint. Don't let anyone tell you "a couple of pumps". Sometimes it can take up to 6 or 8 pumps when it's been in service for a while. You need to do that to flush any contaminants out. This is important. If you're not going to do it, you're better off using sealed u-joints.

If you have u-joints that have the zerk fitting in the end cap (which is what I prefer as it makes lubing the DC end easier) you can replace them with the flush style, as seen on this shaft I rebuilt.

When you're lubing it, if you can't get any grease coming out where shown, then tap the opposite side of the yoke as indicated.

On the slip joint, if you use one, you won't have to remove it and replace the plug every time you want to grease it.

Last edited by antichrist; 09-01-2009 at 11:48 AM.