Engine Issues? :)

#21

Rovahfarm.com is where I get most of my replacements and no, I doubt many brick and mortar parts stores carry them. Rovahfarm is the defacto for parts. AB is known for slipping in AllMakes and charging top dollar which AllMakes isn't. The quality isn't there as they are just a wholesaler. Check em out, decide for yourself.

#22

Pass side is off after wild hunt for socket that would fit the 12pt 8mm bolt head........... Finally found one at lowes

First UGLY ... obviously this has been in place a while, the rubber gasket was cracking

Inside:

Where would the "button" be? ... from what I can tell everything looks in place (other than being coated in way too much carbon)

Aside from running it (and re-hooking up the gas etc) there any other tests to do in here?

First UGLY ... obviously this has been in place a while, the rubber gasket was cracking

Inside:

Where would the "button" be? ... from what I can tell everything looks in place (other than being coated in way too much carbon)

Aside from running it (and re-hooking up the gas etc) there any other tests to do in here?

#23

You would need to take off the four bolts that hold the rocker shaft on, and lift it out as an assembly. I soaked mine in Berryman's carb cleaner and most of that gunk came off. The end of the rocker arm has a ball shape that mates to the push rod, and has an oil port thru the rocker arm to the shaft. The other side of the rocker arm on top of the valve has a different piece of metal to bear on the valve, splash lubed.

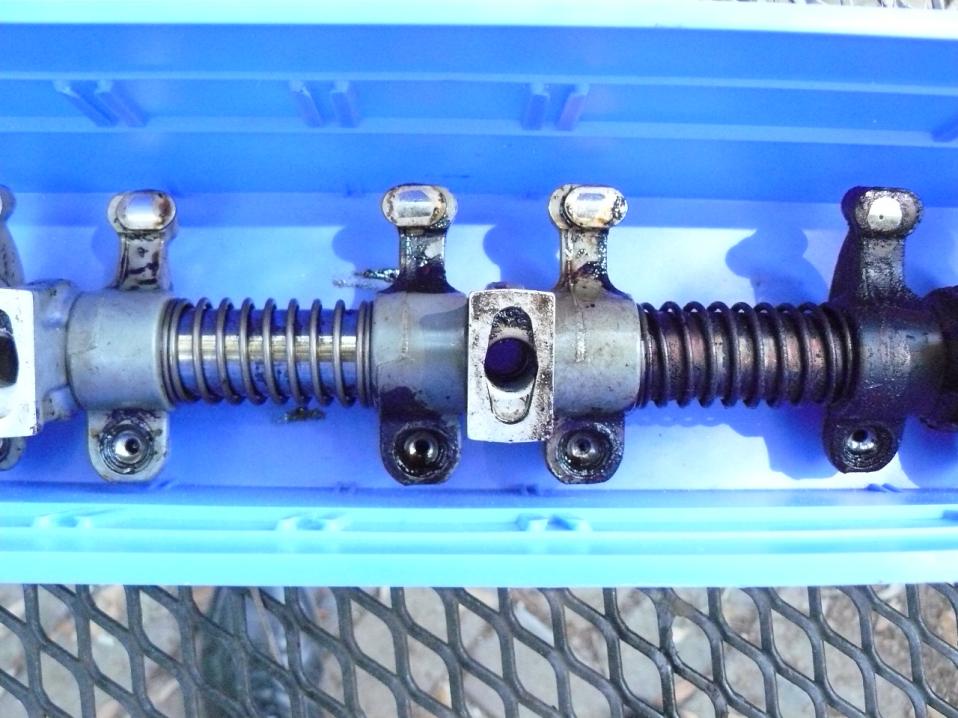

You'ld be wanting to clean up the valve train, the rocker arms compress the springs and slide back to reveal places where you can check for excess wear, touch up with some 1500 grit sand paper (cut is strips and use it like a shoe shine cloth) if not too bad, etc. Small wire good to clean out stopped up oil ports in rocker arms. Pix here is one half of assembly dunked in Berrymans for an hour. WalMArt sells it for like $14 a gallon.

You can see the button contact spots, and the little holes on the other end that get gunked up.

Also, notice that on the valve cover gaskets there are some spacers that are missing, they can fall into the engine or parts unknown.

And that black coolant tank is waiting to burst on you....

Important to keep push rods in order if you pull them out, they'll need cleaning.

You'ld be wanting to clean up the valve train, the rocker arms compress the springs and slide back to reveal places where you can check for excess wear, touch up with some 1500 grit sand paper (cut is strips and use it like a shoe shine cloth) if not too bad, etc. Small wire good to clean out stopped up oil ports in rocker arms. Pix here is one half of assembly dunked in Berrymans for an hour. WalMArt sells it for like $14 a gallon.

You can see the button contact spots, and the little holes on the other end that get gunked up.

Also, notice that on the valve cover gaskets there are some spacers that are missing, they can fall into the engine or parts unknown.

And that black coolant tank is waiting to burst on you....

Important to keep push rods in order if you pull them out, they'll need cleaning.

Last edited by Savannah Buzz; 08-14-2013 at 12:27 AM.

#24

Black tank is on my list to replace, w/o it runnin little chance of probs lol....

this side had all the lil metal inserts for the gasket, but I did find one or two in the oil pan when I had it off, must be from the other side, or at some point they had work done and lost them ...

As for the rest aight, I can pull it and clean it up.. ihscouts mentioned a "button" on the rocker that may fall off... guess i'll find that when I pull the parts out. Was hoping there would be some visual queues that may give an idea whats been goin on but salright

Also, need to make sure valves dont drop down while unhooked from springs?

And any adjustments need to be done after/when I put it back together?

this side had all the lil metal inserts for the gasket, but I did find one or two in the oil pan when I had it off, must be from the other side, or at some point they had work done and lost them ...

As for the rest aight, I can pull it and clean it up.. ihscouts mentioned a "button" on the rocker that may fall off... guess i'll find that when I pull the parts out. Was hoping there would be some visual queues that may give an idea whats been goin on but salright

Also, need to make sure valves dont drop down while unhooked from springs?

And any adjustments need to be done after/when I put it back together?

Last edited by nuclearw; 08-13-2013 at 11:58 PM.

#25

#27

Pulled the valve train and it *SEEMS* like everything is there, the "button"'s appear to be in place though if one was missing would it be that obvious? .. I did notice the one for the rear-most valve was a bit darker than the rest, and the hole appeared to be plugged with crud.. Gonna get the parts cleaner tomorrow, didn't see the one you referenced at walmart (even online .. maybe if you had a link it would help) but Autozone has it for 30$/gallon ..........................

I'll soak it and take some pictures, hoping once some of the crud is outta there it'll be a bit easier to see.

There were also some pads on the valve side of the rockers that seemed pretty "clean" for the most part, a few were stained with burnt oil or something creeping in (not consistantly shiny) ..

after this inspection i'll throw it back in and perhaps try runnin the truck. I can see doing that with the pass side, drivers side however I cannot imagine how that would work? ... re-assemble the plenum and everything?

ihscouts were you able to check out the noise from the video yet since you seem to have the most experience i'm curious to know what u think?

I'll soak it and take some pictures, hoping once some of the crud is outta there it'll be a bit easier to see.

There were also some pads on the valve side of the rockers that seemed pretty "clean" for the most part, a few were stained with burnt oil or something creeping in (not consistantly shiny) ..

after this inspection i'll throw it back in and perhaps try runnin the truck. I can see doing that with the pass side, drivers side however I cannot imagine how that would work? ... re-assemble the plenum and everything?

ihscouts were you able to check out the noise from the video yet since you seem to have the most experience i'm curious to know what u think?

#28

Nope, I'm on dial-up in my neck of the Northern Woods.

Your images are killing me too. I had to disable them so I could pull up the "Quick Reply" box.

Like fish said, it might be a stuffed lifter which means it's either stuck or it's not getting oil - not pumping up.

Ticks in these motors can come from many worn or occluded valve-train components. It's up to you to do the detective work since I can't put eyeballs on what you see.

Shortened push rods, no oiling, sticking valves. Oil enters the rocker shaft and goes out to the components from there. I'd start there and work down towards the lifters. Lifters get their oil from the bore sides, not through the push rods.

In my experience and from what I learning from others it's usually an occluded rocker shaft to start with. Your mounting bolts go through the center of the shaft which is a prime spot for oil to slow, become heated and form a blockage. Follow the Rave, easy.

In order to remove the driver's side valve cover all you have to do is remove the plenum, it's a few bolts. Not a deal buster. It's important.

If I can do a set of head gaskets correctly in less than a weekend (actually less than a day) then I expect anyone can remove a plenum in less time than it takes me to get a cup of coffee at Starbuck's. Game on, get going.

Your images are killing me too. I had to disable them so I could pull up the "Quick Reply" box.

Like fish said, it might be a stuffed lifter which means it's either stuck or it's not getting oil - not pumping up.

Ticks in these motors can come from many worn or occluded valve-train components. It's up to you to do the detective work since I can't put eyeballs on what you see.

Shortened push rods, no oiling, sticking valves. Oil enters the rocker shaft and goes out to the components from there. I'd start there and work down towards the lifters. Lifters get their oil from the bore sides, not through the push rods.

In my experience and from what I learning from others it's usually an occluded rocker shaft to start with. Your mounting bolts go through the center of the shaft which is a prime spot for oil to slow, become heated and form a blockage. Follow the Rave, easy.

In order to remove the driver's side valve cover all you have to do is remove the plenum, it's a few bolts. Not a deal buster. It's important.

If I can do a set of head gaskets correctly in less than a weekend (actually less than a day) then I expect anyone can remove a plenum in less time than it takes me to get a cup of coffee at Starbuck's. Game on, get going.

#29

Nope, I'm on dial-up in my neck of the Northern Woods.

Your images are killing me too. I had to disable them so I could pull up the "Quick Reply" box.

Like fish said, it might be a stuffed lifter which means it's either stuck or it's not getting oil - not pumping up.

Ticks in these motors can come from many worn or occluded valve-train components. It's up to you to do the detective work since I can't put eyeballs on what you see.

Shortened push rods, no oiling, sticking valves. Oil enters the rocker shaft and goes out to the components from there. I'd start there and work down towards the lifters. Lifters get their oil from the bore sides, not through the push rods.

In my experience and from what I learning from others it's usually an occluded rocker shaft to start with. Your mounting bolts go through the center of the shaft which is a prime spot for oil to slow, become heated and form a blockage. Follow the Rave, easy.

In order to remove the driver's side valve cover all you have to do is remove the plenum, it's a few bolts. Not a deal buster. It's important.

If I can do a set of head gaskets correctly in less than a weekend (actually less than a day) then I expect anyone can remove a plenum in less time than it takes me to get a cup of coffee at Starbuck's. Game on, get going.

Your images are killing me too. I had to disable them so I could pull up the "Quick Reply" box.

Like fish said, it might be a stuffed lifter which means it's either stuck or it's not getting oil - not pumping up.

Ticks in these motors can come from many worn or occluded valve-train components. It's up to you to do the detective work since I can't put eyeballs on what you see.

Shortened push rods, no oiling, sticking valves. Oil enters the rocker shaft and goes out to the components from there. I'd start there and work down towards the lifters. Lifters get their oil from the bore sides, not through the push rods.

In my experience and from what I learning from others it's usually an occluded rocker shaft to start with. Your mounting bolts go through the center of the shaft which is a prime spot for oil to slow, become heated and form a blockage. Follow the Rave, easy.

In order to remove the driver's side valve cover all you have to do is remove the plenum, it's a few bolts. Not a deal buster. It's important.

If I can do a set of head gaskets correctly in less than a weekend (actually less than a day) then I expect anyone can remove a plenum in less time than it takes me to get a cup of coffee at Starbuck's. Game on, get going.

Seems like the "Button" is in place though the ones over cyl8 seemed darker than the rest(brown cloud over the metal, not shiny like the rest), got a bucket and some degreaser to clean up the valve train and see what it really looks like, as well as trying to clear out the ports. If its just plenum for the drivers side then cool, i'll get going on that

it does look like there was some blockage in the port over the rear-most lifter(in that tiny port the rocker has)

#30

If your rocker arm assemblys come apart, great. The rockers have that oil port that goes off to top of the pushrod, and oil drools down the pushrod in the normal course of events. There are machined holes in the tube that line up for a moment as rocker rotates, and squirts oil in that moment. If using a spray straw with carb cleaner or such, you have to rotate the rocker slightly to find the hole alignment, so spray will carry thru. That would be if you can't get them apart. The springs easily compress to allow rocker to be slid back and shaft holes cleaned out, minor scrapes cleaned up with 1500 grit, edges of rocker that twist against other parts cleaned up, etc.

I was told to park them in the freezer to make take apart easier, and in my case it made it from "mechanically frozen" to where I could beat it off with a hammer, so I cleaned in place. Too cheap to buy new ones.

I was told to park them in the freezer to make take apart easier, and in my case it made it from "mechanically frozen" to where I could beat it off with a hammer, so I cleaned in place. Too cheap to buy new ones.