I plug welded a customers sleeves.

#11

You don't get it. I'm not welding the sleeve to anything. I'm drilling a hole through the side of the block and plug welding the sleeve in place with stainless wire. Yeah the motor was in the car. It took a long time to do. Think about it, you don't have to weld the sleeve to anything, you just have to put a booger on it so it cant move up and down =).

#12

(Too late. Just seen. ^^)

As you still had to still get access, drill holes and get the welding torch in there is there any bigger benefit than tapping and dropping some machine screws in there instead?

Nicely done.

Kinda thing you do on 'someone else's' vehicle.

#13

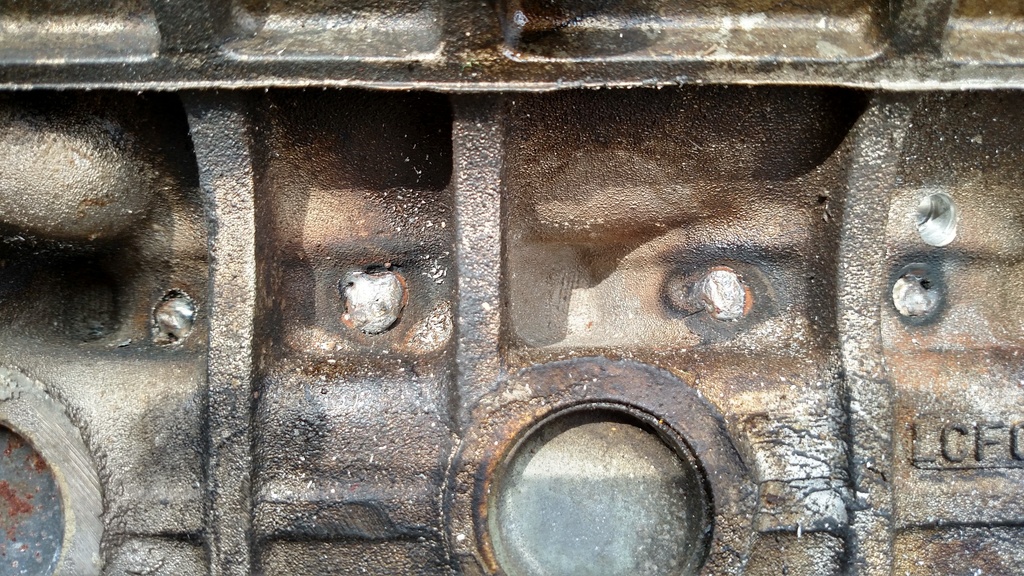

This is what the weld looks like from the inside. (this is a cracked block I had laying around to experiment on.) The stainless wire sticks to the cast sleeve so well that when I tried to hammer the sleeve out it cracked the sleeve and didn't break the weld.

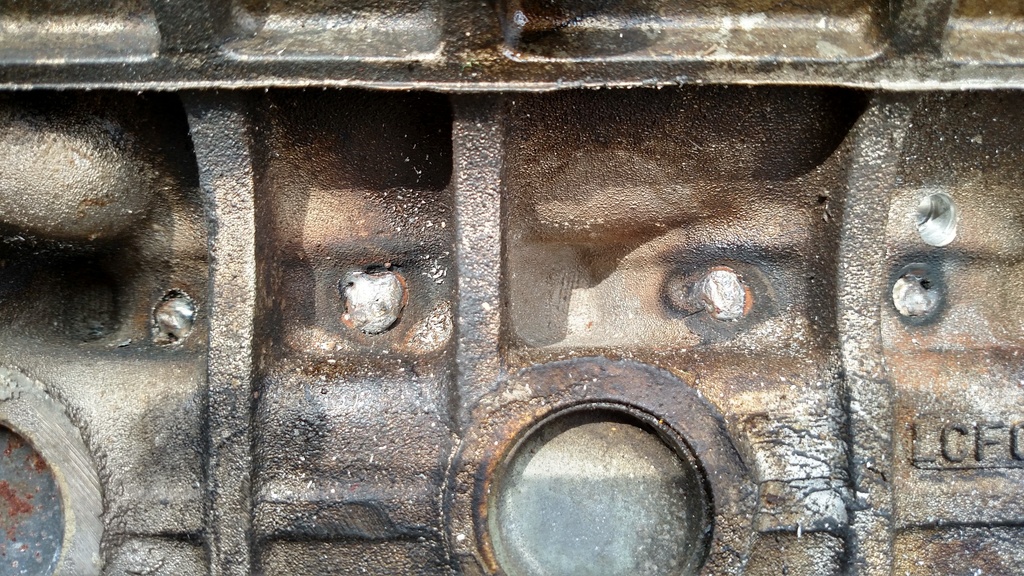

This is what the welds look like from the outside.

If your sleeves are moving, this seems like a good fix. 1500 bucks is a bargain compared to a 5k top hatted motor.

This is what the welds look like from the outside.

If your sleeves are moving, this seems like a good fix. 1500 bucks is a bargain compared to a 5k top hatted motor.

#14

So the weld material, while obviously not fusing to the ally, bulged through the clear hole acting like a pin? And from the outside you just see a welded up block?

(Too late. Just seen. ^^)

As you still had to still get access, drill holes and get the welding torch in there is there any bigger benefit than tapping and dropping some machine screws in there instead?

Nicely done.

Kinda thing you do on 'someone else's' vehicle.

(Too late. Just seen. ^^)

As you still had to still get access, drill holes and get the welding torch in there is there any bigger benefit than tapping and dropping some machine screws in there instead?

Nicely done.

Kinda thing you do on 'someone else's' vehicle.

#15

#16

What about glue? Of course this would only work if the engine is apart so you could pull the liners out. Retaining Compounds : Permatex® High Temperature Sleeve Retainer

#17

I've thought about that for the freelander liners too.... since they only have rightstuff sealing them and they are wet liners. I wonder if you could still use the RTV on the ridge, but coat the top of the liner, in the wet area, with this stuff before installing them. And then letting them completely setup before putting the engine back together.

#18

It wouldn't apply to this situation because as was said before he didn't actually weld the sleeves to the block, but I work in a research lab and we have welded low carbon steel to 6061 T6 aluminum maybe 6 years ago, and I believe we weren't the first one to succeed. The process we used is called Friction Stir Welding or FSW.

#19

1500 bucks to top hat a motor.

So 500 in gaskets and bolts. 12 hours at 100 bucks an hour R+I the motor, and $1200 in liners and machine shop fees = 1500?

You tell me where you got your motor top hat lined out the door for 1500 bucks. I'll recommend all my customers to them.

#20

For a top hatted block not engine(As I stated above)

Apprently whomever you do work for is only conserned with the noise not the state of the engine.

The block was junk before your got to it so i guess its a good test mule.

But it sounds like another temp. fix for a premenent problem.

Apprently whomever you do work for is only conserned with the noise not the state of the engine.

The block was junk before your got to it so i guess its a good test mule.

But it sounds like another temp. fix for a premenent problem.

Last edited by drowssap; 06-08-2015 at 03:07 PM.