I plug welded a customers sleeves.

#64

#65

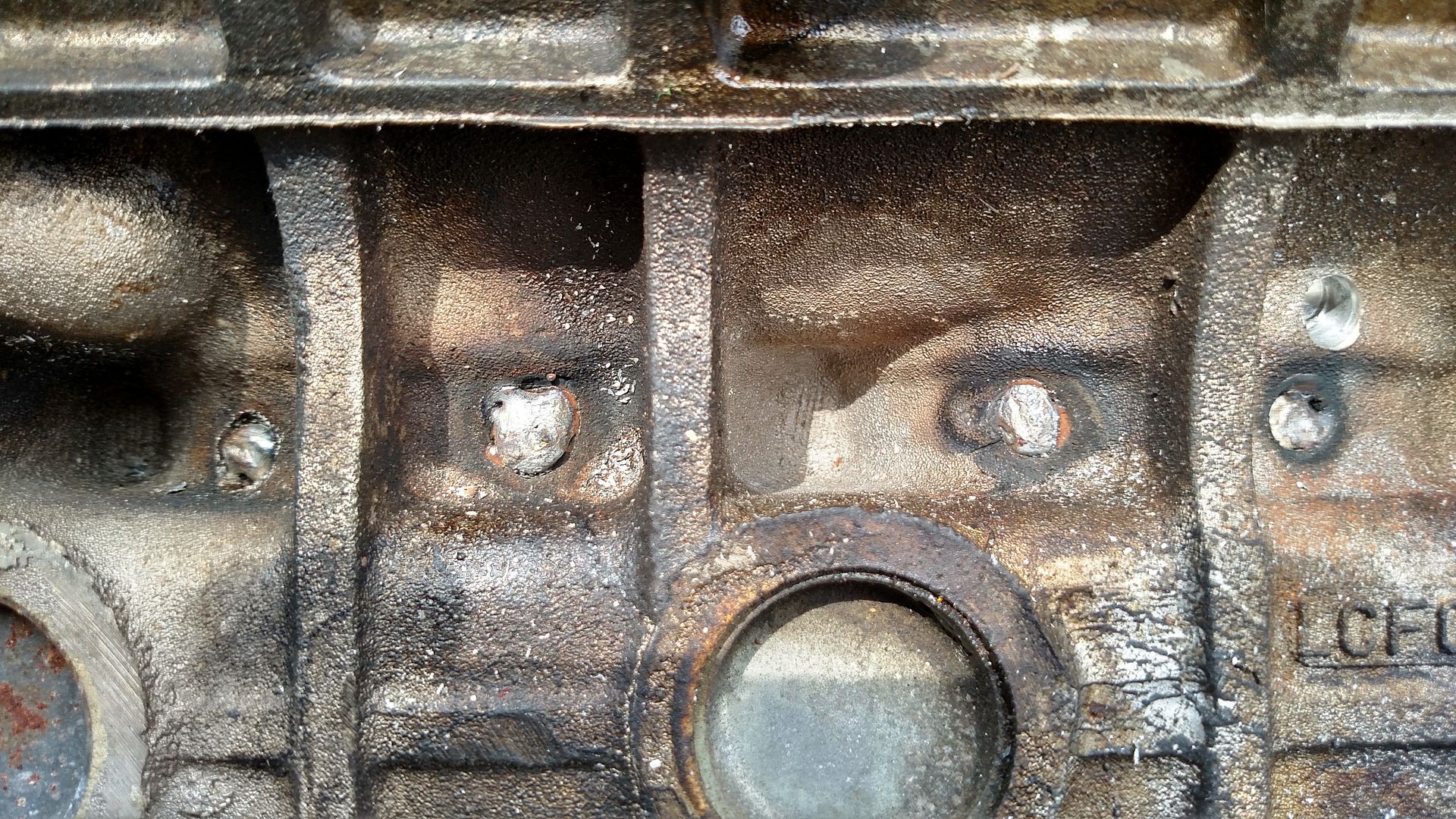

This is what the weld looks like from the inside. (this is a cracked block I had laying around to experiment on.) The stainless wire sticks to the cast sleeve so well that when I tried to hammer the sleeve out it cracked the sleeve and didn't break the weld.

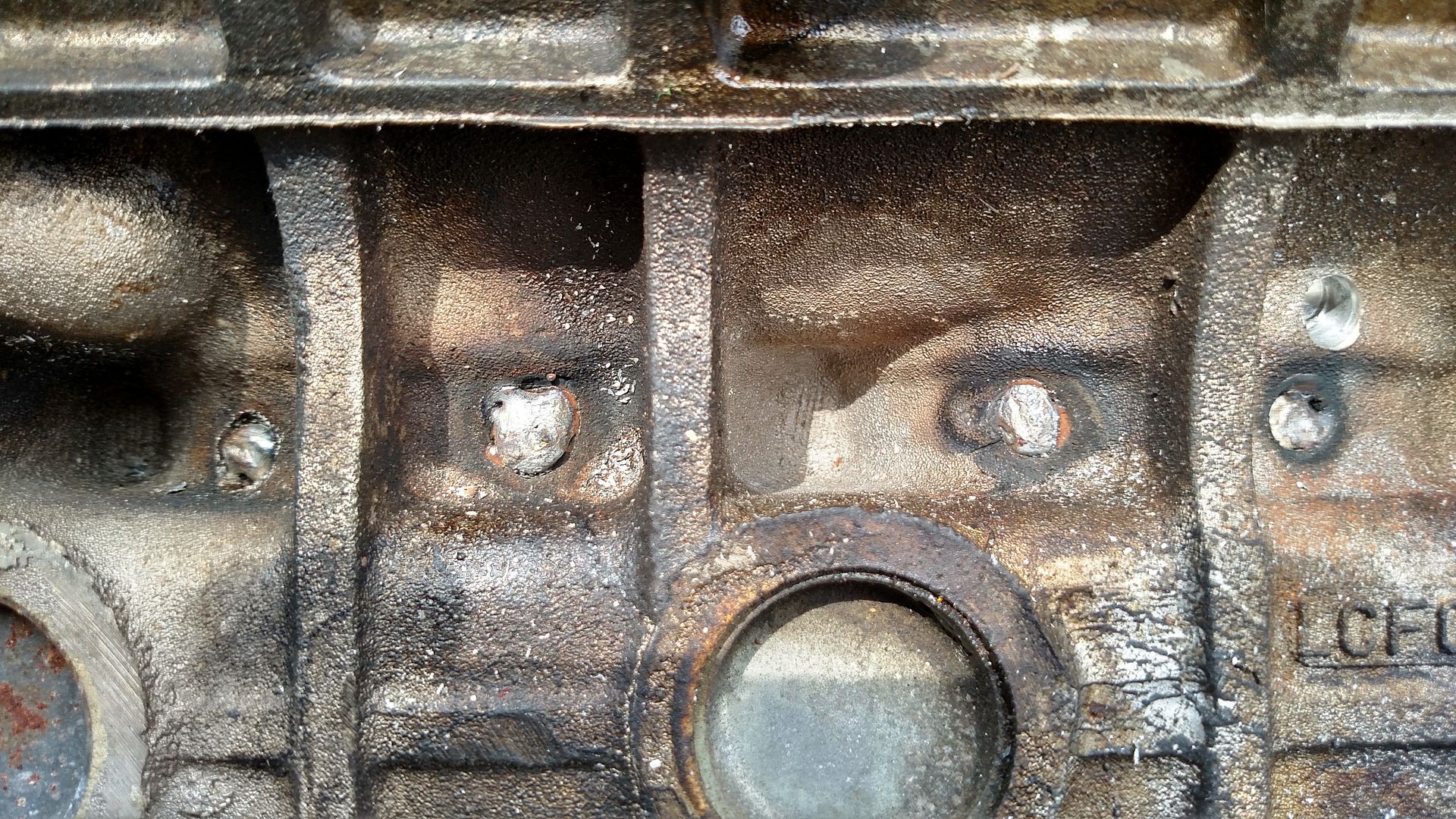

This is what the welds look like from the outside.

If your sleeves are moving, this seems like a good fix. 1500 bucks is a bargain compared to a 5k top hatted motor.

This is what the welds look like from the outside.

If your sleeves are moving, this seems like a good fix. 1500 bucks is a bargain compared to a 5k top hatted motor.

#66

Why is anyone concern about the block been trashed after the repair? you can get a repairable block cheap, actually there is one in Craigslist for $300 in North Jersey, to me this is good fix, don't see it as a permanent solution like a top hat lined block but nevertheless a very clever approach. If someone don't have the budget to spend $5000 plus to rebuild an engine or perhaps have the common sense not to spend all that money in a vehicle that is worth $2500 after is fixed these is certainly a risk that I will take, well done MRT.........

Thread

Thread Starter

Forum

Replies

Last Post