Folding rear seats down - D110

#11

Wow. Ok.

So, the design intent is to use the headrest foam to carry a portion of the weight of the bricks which may be loaded onto the folded down seat back, instead of the force which would be trying to bend the back of the seat through the action of the headrests remaining mounted within the back and twisted downward (as I am doing now).

Well now -- I had no idea!

I will be experimenting later this week ......

Enjoy !!

So, the design intent is to use the headrest foam to carry a portion of the weight of the bricks which may be loaded onto the folded down seat back, instead of the force which would be trying to bend the back of the seat through the action of the headrests remaining mounted within the back and twisted downward (as I am doing now).

Well now -- I had no idea!

I will be experimenting later this week ......

Enjoy !!

The following users liked this post:

D-Fens (06-13-2022)

#15

I ran the test this weekend, converting my "leave headrests in place" approach to the "follow the manual" approach and confirm two things:

1) leaving the headrests in place allows the back of the 2nd row to form a slightly flatter floor (by less than 5 degrees or so) than the manual approach. But, it does so at the risk of a heavy weight bending the metal posts which are installed in the seat back.

2) using the "manual method" allows the seat back and headrest foams to directly carry the heavy load to the grey foam which is in the photo above. The risk of overstressing the head rest mountings are removed.

Conclusion: For a couple of light dogs, the headrests may be left in place safely. For 1000 lbs of bricks, I will always follow the manual's approach.

As I do not use the back seats regularly, I am making the brick hauling setting my standard one.

Enjoy !!

1) leaving the headrests in place allows the back of the 2nd row to form a slightly flatter floor (by less than 5 degrees or so) than the manual approach. But, it does so at the risk of a heavy weight bending the metal posts which are installed in the seat back.

2) using the "manual method" allows the seat back and headrest foams to directly carry the heavy load to the grey foam which is in the photo above. The risk of overstressing the head rest mountings are removed.

Conclusion: For a couple of light dogs, the headrests may be left in place safely. For 1000 lbs of bricks, I will always follow the manual's approach.

As I do not use the back seats regularly, I am making the brick hauling setting my standard one.

Enjoy !!

Last edited by TrioLRowner; 06-21-2022 at 12:57 PM.

The following users liked this post:

GrouseK9 (06-22-2022)

#16

Side note - I'm such an idiot... as I was removing the Torx screws, I turned the bolts the wrong direction and broke the heads off both. I was look down at a weird angle and it threw me off from my well known "rightey tightey, lefty, loosey" rule. I now have to drill out the broken machine screws from within the captive nut and install my own machine screws and bolts to re-install the lower seat.

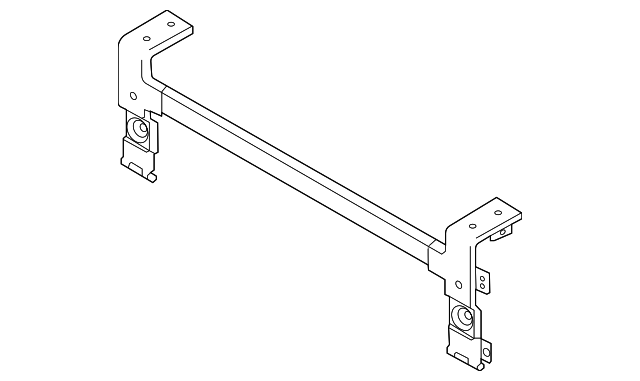

Lesson learned... and I might re-order the bracket and replace to properly fix my mistake. Part #LR132721 (photo below) and if anyone can analyze the screws that I broke and tell me what to order (or I can cannibalize a couple from the foam thing that the seats sit on... they're the same).

Lesson learned... and I might re-order the bracket and replace to properly fix my mistake. Part #LR132721 (photo below) and if anyone can analyze the screws that I broke and tell me what to order (or I can cannibalize a couple from the foam thing that the seats sit on... they're the same).

The following users liked this post:

TrioLRowner (07-11-2022)

Thread

Thread Starter

Forum

Replies

Last Post

C.O.R.E.inMinnesota

Discovery II

13

11-07-2013 07:16 PM