03 4.6 any way to identify/prevent slipper liners?

#32

My truck had a tick every once in a while. But it damn near disappeared with the motorad tstat conversion, HD fan clutch, and brass waterpump. I don't know the science of all of it but my temps were consistently 180-184.5 from then on out and I hardly heard the noise. I wonder if there is a temperature threshold where liner would begin to move. Granted I didn't have a symptom that I would suspect was a bad liner but I did have occasional ticking.

Bottom line is. You do as much as you can for the motor and then you drive the sucker. I would live with the tick over meticulously trying to find the cause or tear down the motor. Might as well LS swap at that point. Just have to admit that LR screwed up and overtaxed an old GM motor to run too hot just so it can fall apart at your 100k mile warranty.

Bottom line is. You do as much as you can for the motor and then you drive the sucker. I would live with the tick over meticulously trying to find the cause or tear down the motor. Might as well LS swap at that point. Just have to admit that LR screwed up and overtaxed an old GM motor to run too hot just so it can fall apart at your 100k mile warranty.

#35

#37

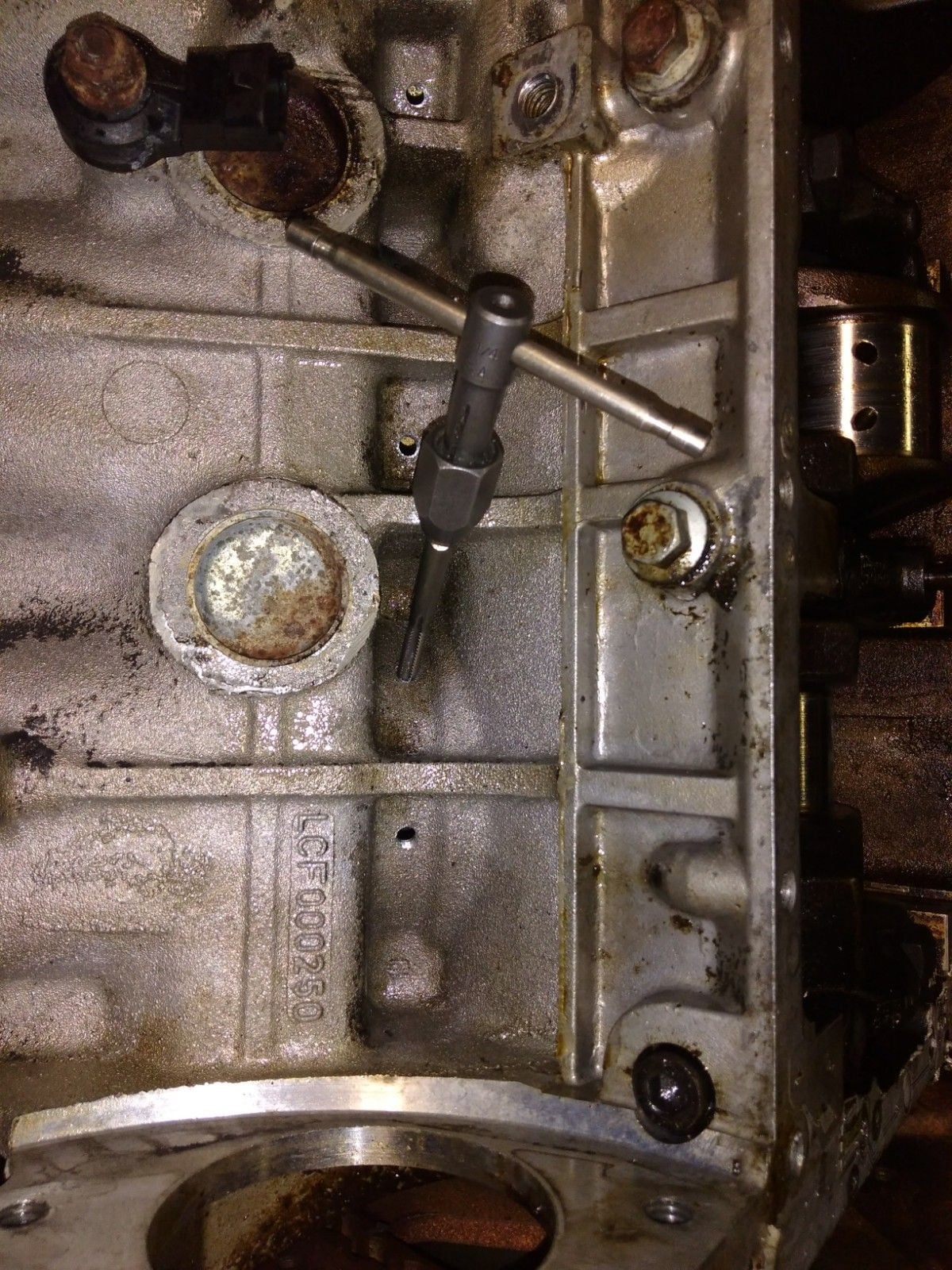

I wish this pinning of liner routine could be performed with engine in place while on creeper. I was going to do it as I know i have a chuck of block off the bottom of one of the cylinders (second from back on drivers side). Got the pan off again and was about to do the pin but there was too many obstructions (motor mount, exhaust).

#38

#39

#40

Per the earlier write-ups the engine mounts do have to be disconnected and removed when doing that side, but that is not very difficult. I need to know your way around a drill and have a reasonably good chance of drawing a perpendicular hole. I would definitely recommend sneaking up on the file size slowly with about three smaller bits so that the final hole is cleaner and straighter because the initial hole is the hardest one to keep straight. I would recommend 5/16 Allen head screws, drilled for safety wire course. Obviously have to move the piston out of the way during the Drilling. I would estimate total time involvement including dropping the pan to be about 6 hours.